Can’t find it? We can probably get it. Ask Us

What We Do

Looking for cutting-edge, innovative engineering solutions to support your business in the retail petroleum, c-store, or other industry? Look no further than Freedom Electronics.

Meet the Team

With a focus on innovative remanufacturing processes, we are committed to reducing waste and promoting sustainability in the industry. Our team of expert industrial, electrical and electronics engineers has a proven track record of developing creative solutions and improvements to meet the unique needs of our clients.

Reasons to Partner with Us

With a focus on best-in-class remanufacturing processes, exceptional quality, and manufacturing of our own brand of products, we exceed the standards set by many OEMs.

Innovation

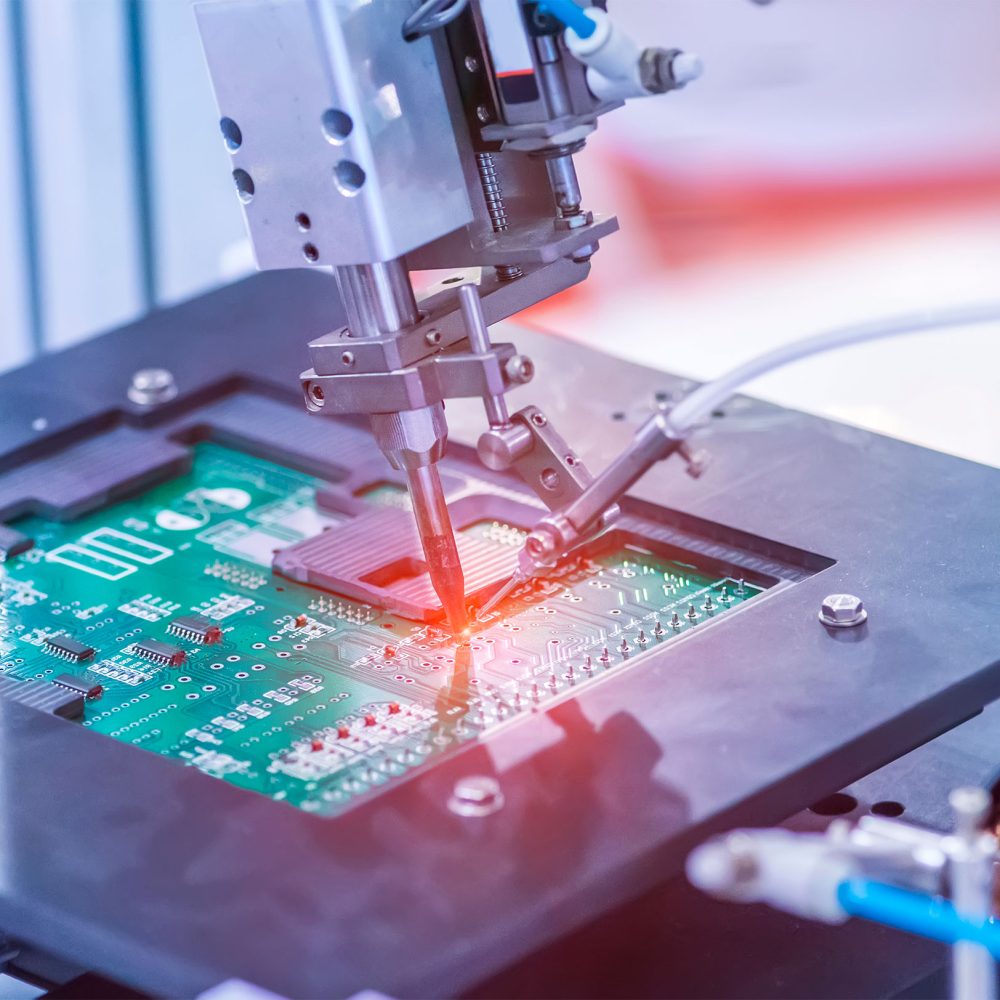

We specialize in addressing common inventory problems associated with multi-generation retail fuel dispenser support. By utilizing advanced coatings, improved inspection technologies, and even artificial intelligence, we’ve been able to streamline and optimize our remanufacturing processes to deliver more efficient and effective results.

Our innovations have also led to the development of more durable and longer-lasting remanufactured products, which translate to significant cost savings in maintenance for retailers. By partnering with us, you can be confident that you’re receiving the best possible engineering solutions to support your business in the retail petroleum industry. Contact us today to learn more.

Design

We design new products that solve inventory problems and delay product obsolescence. OEMs design and market new pumps, creating iterations of fuel pump models that require different parts. To service an evolving model series may require numerous printers or PPU boards. We design retrofits that are field configurable or fit numerous models to reduce the required service inventory. Less inventory, less waste, more profit. Also, many components like microchips become obsolete over the 20-year life of a retail fuel dispenser. We engineer solutions with the existing technology to mitigate supply chain risks.

Processes

We are a cut above the rest. Our best-in-class inspection technologies, combined with the integration of artificial intelligence, make our remanufacturing processes the best in the business. Our brand-wide protocols, knowledgeable engineers, and talented team of repair specialists provide a quality product that keeps working.

Quality

Our products offer the best value. We proudly stand behind the exceptional quality of our manufactured parts. We don’t repair; we remanufacture, which means we don’t only fix what is broken, we replace high-failure components, repaint, and restore the product to like new condition. We want our remanufactured products to be better than new!

Manufacturing

Our engineers understand parts better than anyone. As we engineer solutions for industry problems, we design and manufacture our own brand of products with improved performance for many OEM models. These products are our FE (Freedom Engineered) line and cover a wide range of OEM fuel dispenser models such as Wayne Ovation and Vista; Gilbarco Advantage and Encore, and many others.

Remanufacturing

We build parts better than we found them. We believe every challenge is a chance to make things better! Our remanufacturing process combines research, engineering, artificial intelligence, robust inspection, additional fixes, and TLC for a more durable and longer-lasting product. Our remanufactured products exceed the quality standard of many OEMs. There’s exceptional value in a Freedom remanufactured product.

Join our mailing list

Receive our monthly newsletter and announcements

"*" indicates required fields

Contact & Support

Contact & Support