Can’t find it? We can probably get it. Ask Us

The Circuit – September 2024 Newsletter

News from Our CEO

Greetings!

This month holds several personal milestones for me. September, 30 years ago, I moved from Austria to Los Angeles, ready to pursue the American Dream. The same month, 5 years ago, I joined the great team at Freedom Electronics. That same year, I also became a US citizen. This year, I also turned 50—half a century! Where has the time gone? Well, this is a perfect opportunity to take a moment to reflect.

Here are a dozen things I have learned along the (sometimes hard) way:

- Surround yourself with people that you can learn from.

- Failures are not permanent—they may be temporary setbacks, but you learn more from those than wins.

- Celebrate. Appreciate the good things and share the joy with your family and friends.

- Always be open to learning new things and keep challenging yourself.

- Make few promises but keep the ones you make.

- There are no overnight successes. The road to success takes time and effort. There are no shortcuts.

- You can’t do it alone. At some point, you will need the help of others. Be kind, humble and appreciative.

- Stay physically active. Our bodies don’t do well sitting at a desk. Ask me how I know!

- Set big goals and small tasks to achieve them.

- Don’t complain – take action.

- Prioritize your family!

- Pursue your dreams—life is too short.

Maybe you already have your own list; I am interested to hear about some of the things you have learned along your journey.

Until next month,

Patrick Jeitler

Freedom Electronics President & CEO

Freedom to innovate, power to solve.

Industry News

Join Us at the October 2024 NACS/PEI Show in Las Vegas!

Visit us at booth C6945 from October 7 – 10 to discover our latest Freedom Engineered innovations. We’re showcasing solutions that reduce service parts inventory, improve first-time fix rates, and lower total ownership costs.

Explore Our Latest Innovations Across Major OEMs

Veeder Root ATG

Mag and Mag Plus Float Kits

- FE-846400-00X Mag Plus 4-inch floats (gas and diesel)

- FE-846400-10X Mag Plus 2-inch floats (gas and diesel)

- FE-849600-00X Mag 4-inch floats (gas and diesel)

All kits include 10′ cables, riser adapters, and a cable seal kit

Wayne Ovation

Control Board Button Replacementsand Printers

- Price Control Board without PPUs – FE-WM053972-0001

- PPU – FE-891569-001 LX 5 Product PPU Control Board

- Printers – FE-12 and FE-24: Drop-in replacements for Ovation printers

- This part works well with the FE-WU000805-0005 PTS buttons and the FE-891569-001 LX 5 Product PPU control board.

Gilbarco Encore and Passport

Innovative Parts and Replacements

- PPU – FE-M12893A001: A versatile single PPU SKU that replaces two SKUs

- Cash Drawer – FE-PA01570074: Durable black cash drawer with till insert tray

- Printer – FE-PA040600013: Consolidates multiple SKUs into one

Verifone Systems (C18, Ruby2, Ruby CI, Topaz 310/410)

Peripheral Upgrades

- Printer FE-P040-02-030: Replaces RP-310 and RP-330 with a single SKU

- Cash Drawer FE-P050-01-200: New black cash drawer with cable and till

- Keyboard FE-182-030-01-A: Newly designed C18 keyboard

Visit Our Booth: Stop by Booth C6945 to see these innovations and discuss how we can help your business grow.

Product Spotlight

2″ Float Kits

Freedom 2″ Mag Plus Float Kit for Gas and Diesel

SKU: FE-846400-100 and FE-846400-101

Why Did We Develop This Product?

High customer demand.

When risers get rusted and a 4″ float won’t fit, many times you can use a 2″ float in the riser.

Benefits

- New, in the box, complete 2″ float kits for gas and diesel.

- When those 4″ diesel risers get corroded, use a 2″ Mag Plus float kit.

What is Included?

- This is a NEW product, in the box.

- 10′ probe cable.

- Cable seal kit.

PTS Panel for Ovation-LX

SKU: FE-W2893222-003

Replacement for: W2893222-003

Why Did We Offer This Product?

- Why carry inventory of several parts, when just one part from Freedom will do?

- Fewer parts, more uptime, better first-time fix rate.

- This part works well with the FE-WU000805-0005 PTS buttons and the FE-891569-001 Price Control board.

Benefits

- Built to last longer, with UV inhibitor injected in the material.

- Works for all configurations: removable plugs all placement of buttons as needed.

- Great value over OEM.

What is Included?

- This is a NEW product, in the box.

- Mounting hardware and gaskets.

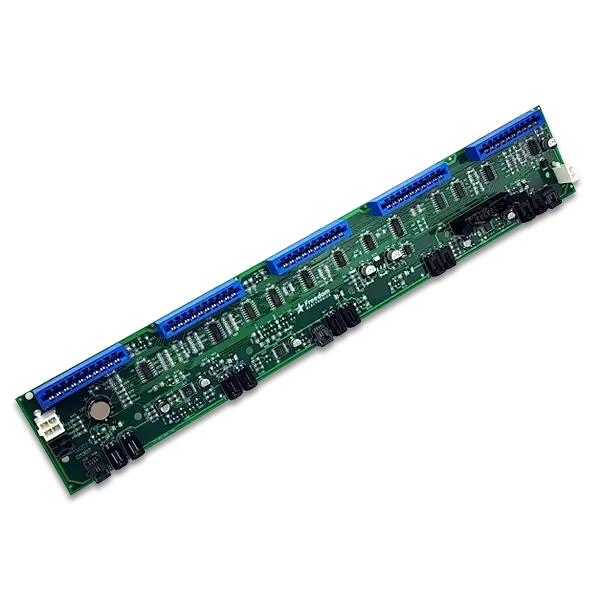

Ovation1 Price Control Board

Freedom 2″ Mag Plus Float Kit for Gas and Diesel

Why Did We Offer This Product?

- This is a high-use board due to the installation geometry. It collects water which leads to corrosion.

- Rebuilding a board with high corrosion is difficult because traces and pads get damaged. Subsurface corrosion is very difficult to completely remove, which leads to more corrosion and failures.

- The only good option has been new from OEM, but that has been pricey. Freedom Electronics created a more cost-effective version.

Benefits

- This is a NEW board.

- No corrosion and no core required.

What is Included?

- This is a NEW product, in the box.

Team Spotlight

Stephen Gorbachov

QC Specialist

Born in Sarasota, Florida, Stephen moved to Georgia at the age of two. As the youngest of four boys, he has been familiar with hard work from an early age. Stephen is the proud father of three incredible children. Currently, he is pursuing a Bachelor of Science in Music Production at the Los Angeles Film School, where he enjoys creating and sharing music.

Stephen began his journey at Freedom Electronics three years ago, starting in the shipping and receiving department. After a few months, he transitioned to the prep department, and shortly thereafter, he was invited to join the quality control team. In his current role as a QC specialist, Stephen is responsible for visual inspections and functionality testing of outgoing boards, consoles, and probes, as well as conducting quality checks on new products and parts. Additionally, he oversees testing and data collection on incoming warranties, ensuring that all products sent to customers meet Freedom’s high standards of quality.

Aftermarket Education

The Aftermarket vs. OEM Debate:

Why Aftermarket Parts Often Come Out on Top

By Chay Chauncey, VP of Sales

One crucial decision when repairing or modifying pump dispensers is whether to use Original Equipment Manufacturer (OEM) parts or aftermarket alternatives. The pump dispenser’s manufacturer makes OEM parts, while aftermarket parts come from third-party companies. While both options have their merits, aftermarket parts frequently prove superior in cost, customization, innovation, availability, and quality.

- Cost-Effectiveness: Aftermarket parts offer significant cost savings compared to OEM parts, which are typically more expensive due to branding and marketing. Benefiting from economies of scale, aftermarket manufacturers can produce high-quality parts at a lower cost, passing the savings on to service providers.

- Greater Variety and Customization: The aftermarket industry often provides a wider range of parts, addressing issues OEMs might overlook. Aftermarket companies focus on the existing product line, offering both standard replacements and specialized solutions. This focus on the current install base allows for more customization, catering to specific needs and correcting OEM shortcomings.

- Innovation and Technological Advancement: Aftermarket manufacturers are often more agile and responsive to market demands than OEMs, enabling them to introduce new technologies and designs more quickly. This flexibility fosters innovation, leading to advancements in materials, performance, and aesthetics that OEMs may not offer.

- Availability and Accessibility: When a pump dispenser model is discontinued, OEM parts can become scarce and expensive. In contrast, aftermarket parts remain widely available, ensuring that older dispensers can continue operating. These parts are also easier to find, and available through various channels, including online retailers and local shops, reducing wait times associated with OEM parts.

- Comparable or Superior Quality: Many aftermarket parts match or exceed the quality of OEM parts. While some low-quality aftermarket options exist, reputable manufacturers offer parts equal to or better than OEM counterparts, often backed by superior warranties. Aftermarket providers typically offer warranties from the date of installation, compared to OEM warranties that start from the date of shipment.

- Competition Drives Improvement: The competitive nature of the aftermarket industry encourages continuous product improvement. Multiple manufacturers vying for market share must innovate and offer better products at lower prices. This competition benefits service providers by ensuring access to high-quality parts with enhanced features at reasonable prices.

While OEM parts have advantages, especially for units under warranty, aftermarket parts often provide superior solutions for pump dispenser repairs and upgrades. Aftermarket parts frequently come out on top with benefits like cost savings, greater variety, innovation, availability, and quality. Service providers who choose reputable aftermarket brands can enhance their pump dispensers’ performance and longevity, making aftermarket parts a compelling choice.

Tech Tip

Stick the Tank

Have you ever pulled an STP motor only to find that the problem was not enough fuel in the tank?

If you have low or no fuel flow, verify that there is enough fuel in the tank first. Don’t trust someone else when they tell you there is plenty of fuel. Don’t trust the ATG readings because floats get stuck, readings can be inaccurate and ATGs fail. Stick the tank. Typically, you will need more than 6” of fuel to dispense any product but this is still scraping the bottom of the barrel, you should have much more than that. You may only make this mistake once but save yourself the hassle and embarrassment of pulling that STP motor for no reason.

EV Charger Repairs

This month we rolled out EV Charger repairs to our production team.

Our Engineering team did a great job identifying and developing repairs for common issues. They documented repair procedures for our technicians and inspection requirements for QC. Engineers then trained technicians. We now have fully trained technicians in both our Kennesaw, GA and Oldsmar, FL facilities.

EV owners now have a high-quality re-manufactured alternative to high-priced OEM chargers. Seven models are now available, with more coming!

Join our mailing list

Receive our monthly newsletter and announcements

"*" indicates required fields

Contact & Support

Contact & Support