Can’t find it? We can probably get it. Ask Us

The Circuit – August 2024 Newsletter

News from Our CEO

Details Matter

Welcome to our August edition of The Circuit. We had a lot of excitement last month. Yes, we released a couple of highly anticipated Freedom Engineered Products. No, that wasn’t the only source of our excitement.

Our Universal Single Level PPU for Encore 700S did not work as intended right out of the gate. Even after completing a rigorous testing protocol, we missed a particular hardware/software combination that caused our board to generate an error and not function as intended. Our engineering team quickly identified the root cause and created a correction plan. The production team reworked our inventory and within a couple of days, we were back in business. While our PPU would work in several applications even without the correction, the right thing to do was to recall the product and issue replacement boards to all customers. Although painful, the lessons learned here will ultimately drive us to be a better organization.

I am sharing this story because in today’s world of social media perfection, we are accustomed to seeing everyone’s highlight reels and we forget that mistakes and failures happen. Few people publicly share their failures. I believe these are our greatest opportunities to grow and improve. One little detail missed caused quite a bit of stir in our organization. Speaking of details, do you know the difference between repaired and remanufactured? Check out the article below by Chay Chauncey on why you should choose one over the other.

Until next month,

Patrick Jeitler

Freedom Electronics President & CEO

Freedom to innovate, power to solve.

Industry News

Understanding the Impact of the Mastercard/Visa Class Action Settlement on Retail Petroleum Marketers

The recent class action settlement against Mastercard and Visa has been a hot topic across various industries due to its implications on swipe fees. Unfortunately, for Retail Petroleum businesses, the settlement offers little solace. Despite hopes for relief, the agreement leaves a significant loophole that allows Mastercard and Visa to continue imposing high fees.

Key Details of the Settlement: The settlement highlighted ongoing challenges in the payments industry, particularly the ability of credit card giants to maintain high transaction fees. This situation underscores the need for businesses, especially in Retail Petroleum, to seek alternative ways to manage these costs effectively.

Benefits of Choosing Freedom Electronics:

- Cost Savings: Businesses have reported substantial savings by opting for Freedom Electronics’ parts, alleviating some of the financial strains caused by high swipe fees.

- Increased Profits: Lower maintenance costs translate directly into better profit margins, making it a smart business decision to choose Freedom parts.

While the Mastercard/Visa settlement may not have ended high swipe fees, proactive measures by companies like Freedom Electronics ensure that Retail Petroleum marketers have viable options to control costs and boost profitability.

For more information on how Freedom Electronics can help you manage costs and enhance service delivery, please contact a sales representative. Together, we can navigate these challenges and continue to thrive in a demanding economic landscape.

Product Spotlight

Avalan Wireless Forecourt Communication System

Avalan Wireless Forecourt Access Point and Avalan Wireless In-Dispenser Unit

Why Do We Offer This Product?

- Gilbarco and Wayne distributors want to be able to get this product quickly and easily.

- Wireless communication that is this easy to set up makes sense.

SKU: AW58EMVAP

SKU: AW584EMVSU

Benefits

- OEM forecourt communication system

- Plug-and-Play wireless ethernet

- No digging up conduit for conversion to EMV

What is Included?

- Wireless Forecourt Access Point comes with an antenna, power supply, mounting bracket, and pairing key

- Wireless In-Dispenser Unit comes with power cable, USB key, adhesive, and mounting bracket

Freedom Cash Drawer for Passport

Get more value for your money! Why pay $605 OEM list price for a NEW cash drawer? For $195, you can buy a new cash drawer for your Passport from Freedom.

SKU: FE-PA01570074

OEM: PA01570074, PA01570080, PA011570081

Benefits

- NEW cash drawer painted black

- Only available from Freedom Electronics

- A drop-in replacement for PA01570074, PA01570080, PA011570081 but with a much better value

- Includes a till insert tray

Team Spotlight

Kelly Absher

Senior Account Executive

Tenure: 20 Years

Kelly has spent her entire professional career in the services industry. As a child, she learned the importance of customer service from her father, an entrepreneur in the Service Industry. She spent time developing professional skills as a Service Manager in the Petroleum Service Industry. After that, she wanted to gain perspective so she took a job with a Convenience store operator. Making a name for herself and her technical expertise she moved into a role with Dover Fueling Services where she served the petroleum industry as a Regional Service manager and eventually moved into managing this team.

Kelly’s technical expertise was exactly why Freedom Electronics offered her our Senior Account Executive role in the Northeast. She brings a perfect mix of technical expertise as well as customer relationships. She fits into the culture of our company and we could not be more excited to have her on our team.

Elbis Martinez

Customer Service

Elbis Martinez was born and raised in Cuba, and moved to the US just out of high school. She enjoys being a mother of two adult children who are currently attending College at UF. She also enjoys sporting events, traveling, and decorating as often as she can. She loves hanging out with her family and her dogs.

Elbis started working at ESCO/Freedom 17 years ago, starting in shipping and receiving, and then moving to logistics. She enjoyed Logistics but she is a people person so she made the move to Customer Service. She enjoys helping customers get what they need while delivering the best customer experience possible.

We value Elbis’ friendly, upbeat attitude with our customers. She’s a great problem solver and truly a joy to have on the Freedom Electronics team.

Aftermarket Education

Renewing Your Products: Repair vs. Remanufacturing

By Chay Chauncey, VP of Sales

In our industry, the choice between repair and remanufacturing can greatly affect your budget and product availability. Here’s a brief look at the key differences between these two approaches:

Repair

- Definition: Fixes the specific issue without addressing other potential wear and tear.

- Pros: Quick and relatively inexpensive, ideal for minor damage.

- Cons: May not provide a long-term solution if the underlying cause isn’t thoroughly addressed.

Example: For a Wayne Ovation 1 pump printer with a jamming issue, we not only repaired it but also re-engineered it with a direct paper path for better performance.

Remanufacturing

- Definition: Involves disassembling the product, replacing worn-out components, and restoring it to like-new condition.

- Pros: Extends product lifecycle, minimizes waste, and often enhances performance beyond the original specs.

- Cons: More comprehensive and may involve higher upfront costs.

Key Differences

- Scope of Work: Repair fixes immediate issues, remanufacturing overhauls the entire product.

- Longevity: Remanufacturing significantly extends product lifespan.

- Quality Assurance: Remanufacturing includes rigorous testing, unlike some repairs.

- Environmental Impact: Remanufacturing reduces waste and conserves resources, aligning with sustainability goals.

Which Option Is Right for You? The choice depends on the extent of damage, budget, and sustainability goals. Repairs offer a quick fix, while remanufacturing provides a long-term, environmentally friendly solution.

Remanufacturing is a holistic approach that ensures long-term value and sustainability, renewing your product’s potential and positively impacting both your bottom line and the planet.

Tech Tip

Don’t Trust Breaker Labels

Has this happened to you?

I have experienced and know several techs who have been sprayed with fuel due to not shutting off the correct breaker. Double-checking would have prevented it. Breakers are often mislabeled or not labeled at all. It is important to know the equipment you will be working on has no power for your safety, the people around you, and the equipment itself. Always verify power has been removed from the equipment you are working on by attempting to operate it after the breaker has been turned off. Having an STP unexpectedly turn on while changing a check valve or leak detector can be a major safety issue, and you don’t want to take a fuel shower!

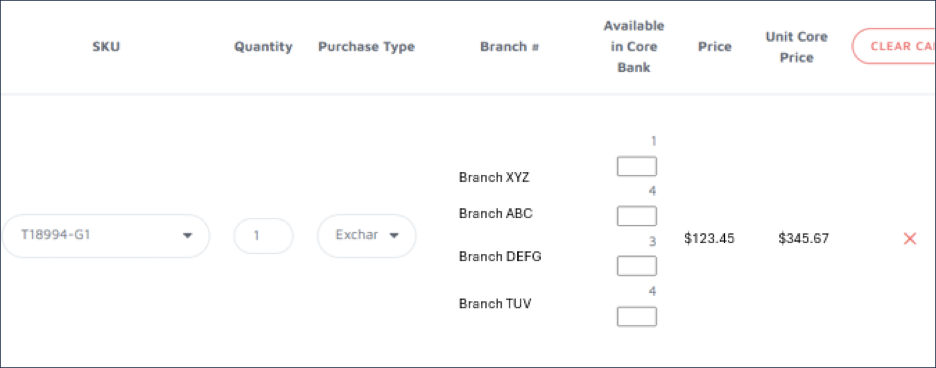

Enhanced Core Management Program

Streamline Your Operations with Our ECM Program

Managing cores is a common pain point we hear about from customers like you. Non-functional parts pulled out on service calls (“cores”) are vital for the robust third-party remanufactured parts market. However, consolidating, managing, and leveraging them for lower-cost exchange orders can be a significant operational burden. That’s where our ECM (Enhanced Core Management) program comes in.

Our ECM program simplifies the entire process for you. We inventory your cores and provide real-time status updates via our website. Even better, our system automatically applies your cores to orders, eliminating the hassle of managing cores and ensuring you never miss an opportunity for savings.

Key Benefits of the ECM Program

Real-Time Inventory Management

Access your core inventory status anytime through our user-friendly website.

Apply Cores with the Click of a Button

Your cores are automatically applied to orders, saving you time and effort.

Sell Your Cores for Cash

Offer your cores for purchase through our website and receive offers from our purchasing team, all in the easy-to-use website.

Customized Solutions

Have a complex or multi-branch operation? Our ECM program is tailored to support your unique needs.

How to Get Started with ECM

Whether you’re new to the ECM program or need a refresher, follow these simple steps to streamline your operations and maximize savings today:

- Implementation: Consolidate your cores and contact your sales representative to coordinate a freight pickup. We will cover the initial shipment!

- Core Return: Ship your cores to us weekly, monthly, or in bulk to resupply your core bank. We handle the inventory for you.

- Use Your Cores: Use our website to place orders and apply your cores seamlessly.

Need Assistance?

Already an ECM user but not familiar with the website? Call your sales representative or our customer service team now for a quick refresher on using this simple interface.

Join our mailing list

Receive our monthly newsletter and announcements

"*" indicates required fields

Contact & Support

Contact & Support